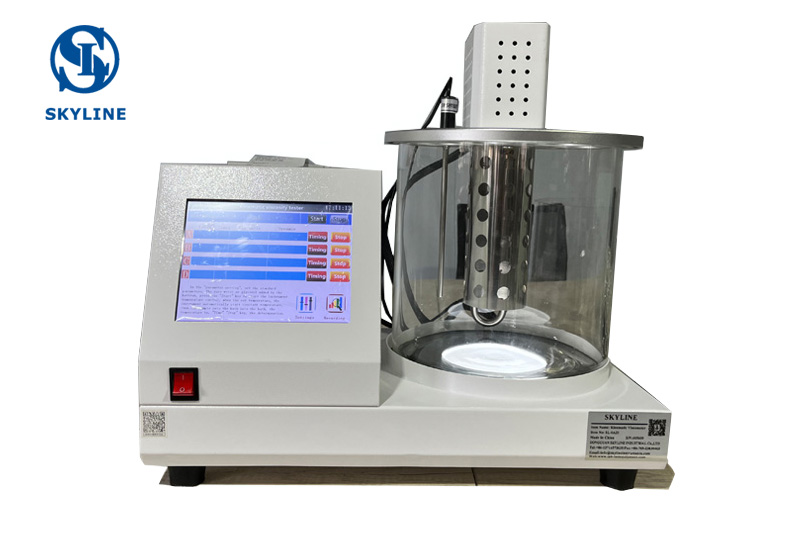

In recent news, a new Copper Strip Corrosion Test Apparatus has been developed by a team of researchers in the field of material science. The apparatus is designed to measure the corrosion resistance of various materials, particularly metals and alloys, in the presence of fuels and lubricants.

The Copper Strip Corrosion Test Apparatus is an important tool for industries that rely on the performance of metals and alloys in contact with fuels and lubricants, such as the automotive and aerospace industries. The test measures the ability of a material to resist corrosion in the presence of a fuel or lubricant, and is a critical factor in determining the durability and longevity of metal components.

The new apparatus features an advanced design that allows for more precise and accurate measurements of corrosion resistance. It also has a user-friendly interface that makes it easy to operate, and can be customized to suit the specific needs of different industries.

The development of the Copper Strip Corrosion Test Apparatus is a significant advancement in the field of material science and is expected to have a major impact on industries that rely on metal components. With the ability to accurately measure the corrosion resistance of various materials, companies can make informed decisions about which materials to use in their products, ultimately leading to longer-lasting and more reliable products.

The team of researchers responsible for the development of the Copper Strip Corrosion Test Apparatus is excited about the potential impact of their invention and is looking forward to seeing it put to use in various industries. They believe that this new tool will help to improve the performance and durability of metal components, leading to better products and greater customer satisfaction.